What is Steel Detailing in Infrastructure projects?

The Saskarc Design & Detailing Differentiator in Infrastructure & Construction - Chapter 1

TL;DR

Steel detailing is the unsung hero of big infrastructure and excavation projects. It takes an engineer’s design and turns it into clear, buildable instructions, i.e., shop drawings, material lists, and erection drawings, that keep fabrication smooth and site crews safe. When detailing is done right, projects run faster, cheaper, and with fewer headaches. When it’s done poorly, everything from delays to budget blowouts can follow. In this article, we break down what steel detailing really is, why it’s so important for infrastructure projects, and how getting it right early can save time, money, and a lot of frustration on site.

Table of Contents

Steel Detailing: Transforming Design to Reality

Every landmark project – whether it is a bridge, a high-rise, or a complex underground excavation, shares one truth. Success depends on precision. Engineers may design the vision, but it is steel detailers who make it buildable. Without them, even the most brilliant engineering design is like a recipe without instructions or a symphony without sheet music.

Steel detailing is the critical step that translates engineering concepts into clear, actionable plans for fabrication and installation. And when it’s overlooked or rushed, projects don’t just get delayed, they can collapse under the weight of costly mistakes.

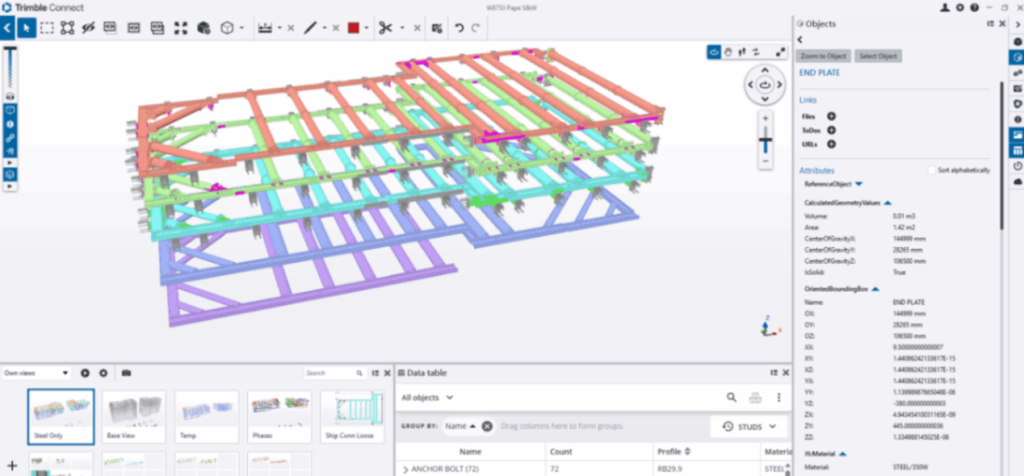

Detailing is the process of translating engineering design drawings, filled with complex intent and calculations, into clear, precise shop drawings that fabricators and erectors can follow. A steel detailer takes that information and breaks it down into precise shop drawings that specify dimensions, shapes, material grades, and exact fabrication and assembly steps. Showing exactly how each part should be cut, bent, welded, or bolted together.

In other words, if engineers provide the design, steel detailers provide the roadmap to make it real. Steel detailing is the silent backbone that makes construction possible — safely, accurately, and on time.

At Saskarc, we have seen it all. Projects that soared because detailing was done right, and projects that stumbled because it was rushed, cheap, or ignored. What many don’t realize is that cheap steel detailing and not giving it the focus it deserves is often the most expensive choice a client can make.

So What is Steel Detailing?

Imagine an architect sketching a dream house. That sketch is inspiring, but it’s not enough to actually build. Someone has to prepare the builder’s manual. Exact dimensions, material lists, connection methods, and instructions for assembly. That’s what a steel detailer does.

At its core, steel detailing is the bridge between engineering and construction. Engineers and architects design intent drawings that define what needs to be built. Detailers then interpret those drawings into precise fabrication models and shop drawings that define how it will be built.

Steel detailing is the process of taking engineering design drawings, specifications, and calculations and transforming them into highly detailed fabrication and erection instructions. In simple terms, it removes the guesswork. Every part, connection, and assembly is defined to industry tolerances so that the fabricator and erector know exactly what to build and how it should fit together.

Steel Detailing Components

Steel detailing involves a few components. Let’s have a look.

Shop drawings

are the foundation of the process. These are detailed sheets and reports that precisely outline each part, its dimensions, material grade, and fabrication requirements. Providing details on whether it needs to be cut, bent, rolled, welded, or bolted. They give the fabrication shop a clear roadmap to produce ready to install components that will eventually arrive on site.

Shop drawings

are the foundation of the process. These are detailed sheets and reports that precisely outline each part, its dimensions, material grade, and fabrication requirements. Providing details on whether it needs to be cut, bent, rolled, welded, or bolted. They give the fabrication shop a clear roadmap to produce ready to install components that will eventually arrive on site.

Erection drawings

on the other hand, do the work of providing assembly instructions like in a Lego set. They show where each part belongs, its size, weight, and how it connects to the system around it. The erection contractor uses these drawings to develop an erection plan that must be reviewed and approved by an engineer to ensure the structure can be assembled safely. In this stage, lives are directly at stake. A missing tie-off or reinforcing step could put crews in danger.

Erection drawings

on the other hand, do the work of providing assembly instructions like in a Lego set. They show where each part belongs, its size, weight, and how it connects to the system around it. The erection contractor uses these drawings to develop an erection plan that must be reviewed and approved by an engineer to ensure the structure can be assembled safely. In this stage, lives are directly at stake. A missing tie-off or reinforcing step could put crews in danger.

Bill of Materials (BOM)

supports both sets of these drawings. This list drives purchasing, kitting, and assembly by ensuring the right material is ordered, received, and prepared for fabrication. A complete BOM reduces wasted handling and keeps projects moving efficiently.

Bill of Materials (BOM)

supports both sets of these drawings. This list drives purchasing, kitting, and assembly by ensuring the right material is ordered, received, and prepared for fabrication. A complete BOM reduces wasted handling and keeps projects moving efficiently.

Why Detailing Matters in Infrastructure Projects

Infrastructure projects, for example, bridges, plants, civil foundations – are unforgiving. They are expensive, highly visible, and built on immovable schedules.

When steel detailing is done right, i.e., when drawings are accurate, sequencing is logical, and connections are constructible, it reduces errors, eliminates rework, and speeds installation. The project runs like clockwork. Install goes faster. Fabrication starts smoother. Calls from the site dry up. Everyone looks good.

When done poorly, for example, a missing dimension, mislabeled part, an incorrect bolt grade, an overlooked full-penetration weld that isn’t properly flagged for testing or an overlooked splice, causes cascading failures. Delayed site work, extended equipment rentals, ballooning labor costs, RFIs piling up, back-charges, and frustrated crews are the unfortunate outcomes. Likewise, failing to include every item in a Bill of Materials (BOM) can halt fabrication, delaying the entire project and leading to costly on-site improvisation.

Now, while this article looks at steel detailing in the broader context of infrastructure projects, support of excavation brings its own unique challenges. We explore those in detail in our follow-up piece on steel detailing for SOE projects.

What is the Cost Impact of Steel Detailing on Infrastructure Projects?

Remember – every dollar saved in detailing multiplies in the field.

We have seen how $15/hour detailing decisions can lead to thousands in rework. Every missing dimension, mislabeled part, or overlooked splice creates headaches in the shop and even bigger ones on site.

And here is the truth. No matter how well an engineer designs, or how skilled an erector is, if the detailing is wrong, the project suffers.

At Saskarc, we know that detailing isn’t just drawing steel. It’s preventing disasters.

Our experienced steel detailers, trained on our proprietary Saskarc Detailing Standard, are constantly reviewing designs for practical challenges. They identify welds that may be hard to access in the shop, bolts that could be difficult to reach on site, or assemblies that might be impossible to fabricate as drawn.

Detailers collaborate with fabricators and engineers, proposing workable solutions that are reviewed, validated, and sometimes recalculated to ensure safety and efficiency. This proactive approach saves time and prevents expensive rework.

On the other hand, projects with incorrect detailing potentially cause mayhem. On one infrastructure project, misnumbered connection clip angles and incorrect quantities caused missing pieces at the erection site, halting progress and generating significant cost overruns. The experience highlighted that cutting corners on detailing is very expensive in the long run. What may seem like a small saving in design costs can multiply many times over in fabrication, rework, and delays.

In short, clients may not need to think about the day-to-day work of steel detailers, but they absolutely need to ensure competent detailing is part of their project. Time, safety, and money all depend on it.

“Every mistake in detailing multiplies in the shop and on site.”

“Every mistake in detailing multiplies in the shop and on site.”

Infrastructure work is unforgiving, but when it comes to deep excavations, the stakes climb even higher. If you’re interested in how detailing directly affects SOE projects, and the costly consequences of getting it wrong, check out our article on steel detailing for excavation support.

Pro-Tip

How Can Infrastructure Projects Reduce Costly Errors & Maintain Schedules?

At Saskarc, we always recommend our clients to award detailing early. When detailers are involved from day one, they can identify challenges, optimize connections, and often save costs far beyond their fees. So, Early Contractor Involvement (ECI) is a best practice all projects should implement.

Pro-Tip

How Can Infrastructure Projects Reduce Costly Errors & Maintain Schedules?

At Saskarc, we always recommend our clients to award detailing early. When detailers are involved from day one, they can identify challenges, optimize connections, and often save costs far beyond their fees. So, Early Contractor Involvement (ECI) is a best practice all projects should implement.

Why Award Detailing Early

One project highlighted the value of collaboration. Our detailer joined a client and EOR (Engineer on Record) call to resolve an installation conflict. The EOR explained their intended installation style, which initially clashed with the erector’s plan. By collaborating directly, we aligned the design with the erection method.

The Result?

Smooth installation, minimal site calls, and a client grateful for a seamless process.

“The earlier the detailer is at the table, the fewer problems you’ll face in the field.”

In Conclusion

Steel detailing isn’t just another step in the process—it’s what makes projects buildable. The drawings, material lists, and erection with drawings detailers produce are the link between an engineer’s design and a safe, working structure on site. When detailing is done well, jobs move faster, crews face fewer surprises, and costly rework is avoided. When it’s rushed or overlooked, delays, overruns, and safety risks follow.

For infrastructure and support-of-excavation projects, the takeaway is simple: bring experienced detailers in early. A small upfront investment in good detailing saves far more in time, money, and headaches once steel hits the ground.

Steel detailing is the process of converting engineering design drawings into precise fabrication and erection instructions. This includes shop drawings, erection drawings, and bills of material (BOM), ensuring every steel member is cut, welded, and installed accurately.

In SOE projects, components like struts and walers hold back thousands of tonnes of soil and water. Accurate detailing ensures these heavy, temporary steel systems fit together correctly, reducing safety risks, avoiding delays, and keeping the project on schedule.

- Shop Drawings: Instructions for fabricating each part.

- Erection Drawings: Step-by-step guidance for safe assembly on site.

- Bill of Materials (BOM): A complete list of materials and components for purchasing and fabrication.

Poor detailing can lead to misfabricated parts, site delays, excessive RFIs, rework, and even safety hazards. A single missed splice or mislabeled material can cause weeks of delay and cost overruns, way more than the cost of hiring qualified steel detailers.

The most effective approach is Early Contractor Involvement (ECI). Involving detailers early allows them to flag potential issues, optimize connections, and adapt drawings before fabrication, saving both time and money. Equally important is choosing the right partner. Firms like Saskarc bring the experience, technical know-how, and attention to detail needed to catch errors before they escalate. This is critical on large infrastructure and construction projects like subways, nuclear plants, water & waste water tunnels, where the stakes are high. By working closely with project teams, they provide guidance that helps keep schedules on track, minimize risks, and control costs more effectively.

Saskarc combines detailing with practical construction insight. Our team doesn’t just translate drawings. We anticipate challenges, optimize connections, and collaborate with engineers and erectors to prevent problems before they reach the site.